Glass

Float Cold End, Automotive, Solar

Created by a branch of ABB, STAR has inherited its complete system capabilities and extensive process knowledge about the most advanced glass processing solutions.

Our Customers are world's largest multinational groups such as AGC, Fuyao, Guardian, Keraglass, Pilkington, Prevent Glass, Soliver and Zeledyne. Focus on customers and their production needs are a key Value for STAR.

Belonging to ICAPgroup, STAR has two main offices: Italy and China that serve the needs of the automotive and architectural glass industries worldwide.

STAR is also an ABB Certified System Integrator for robotized glass applications and acquired all ABB patents and know-how related to the glass robotic industry.

In glass industry our business can be summarized in the following groups of activities:

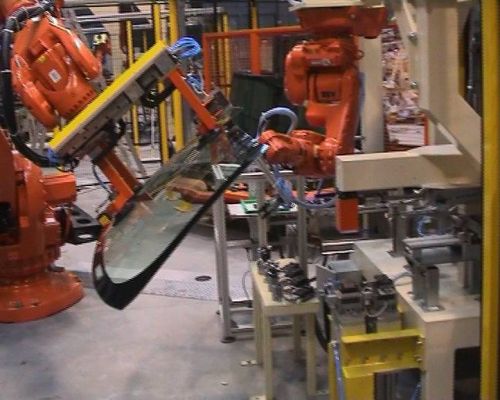

AUTOMATIC ASSEMBLY OF WINDSHIELD

- Cycle Time: 12-20 sec- Automatic pattern change- Vision systems to center PVB and to guide the cutting knives- Vinyl peel-off from stack- PVB sheet handling- Glass handling & squaring- PVB robotic cutting- PVB Excess evacuation

More details

AUTOMATIC PVB TRIMMING

- Cycle Time: 12-20 sec- Feedback control of applied force on the edge of the glass- Auto blades change- Auto pattern change- “Soft core” cutting blades- Off-sets to cutting parameters from HMI- IRC5 control unit for multiple robots- From one up to three robots in the trimming process...

More details

BENDING IRON MEASUREMENT SYSTEM

- Detecting of bending iron centring points deformations- Detecting of bending iron perimeter deformations- Software interface with line PLC- On-line display of the measures- Measurement time: 15 sec- Vision system- 2 Laser sensors- Data storage in Access DB- In-line measurement

More details

CLEAN ROOM PVB CUTTING

- Vision assisted cutting- Cutting time up to 13 sec- Changing (in cycle) blade- PVB debris collection- White/colored PVB separation after cutting

More details

REAR MIRROR SOCKET & RAIN SENSOR APPLICATION

- Automatic system for the positioning and gluing of mirror sockets & rain sensors onto automobile windshields in a production line.- Gluing materials - PVB (heating + pressure) - Pre-Gluing with Hot Melt - SOTEFA (pressure) - 3M tape...

More details

THE GLASS AUTOMATIC SHAPE CHECK

- Measure with contact sensors (LVDT) Measure resolution : 40 um - Measure repeatibility : ± 0.01 %- Measure of slope, cumber, surface, dimension- Measure time < 2 sec.

More details

Automatic Float Unloading

- Cycle time: 9-12 sec for single plates- From 2 up to 16 robots in the process- Glass range: 400 x 600 mm / 3660 x 2700 mm- Thickness: from 1.6 to 12 mm- Stacking accuracy +/- 3 mm- On the fly picking- Rejected glass defects: dimensions, cracks, edge, ink marks.- Grippers configuration with glass...

More details

MICRO-FLOAT SHEETS PACKAGING

- Size of glass sheets : 500x500 mm to 1900x1400 mm- Thickness : 0.85 to 3.5 mm- Cycle Time : 8,5 sec- Automatic packages identification based on laser sensors- Semi-automatic variation of gripper dimensions

More details

AUTOMATIC CLIP SOLDERING ON HEATED BACKLIGHTS

- Energy feedback controlled- Automatic clip feeding- In-line soldering quality control (Pull-test)- Cycle time: 10 sec- In-line automatic electrical checking of heater grid- In-line automatic labeling with process parameters

More details

AUTOMATIC LOADING & UNLOADING OF BENDING LEHR

The system:- Robot with squaring tool- Vision system for location of the bending iron- System to open the balanced mobile sides of the bending iron (when required)- Conveyors (Inner & outer glasses)The advantages:- Reduction/cancellation of ergonomic problems- Reduction of production lost rate...

More details

ELECTRICAL CHECK OF HEATED BACKLIGHTS

- 100% Check of the electrical characteristics of heated backlights- Busbar abrasion- Continuity- Resistance Measurement- Glass Temperature Measurement- Mark / Tractory of defective backlights- Statistical dataMain features:- Range 0.3 - 5 ohms- Cycle Time: 12 seconds- Accuracy ± 0.01 ohm-...

More details

Paper Machine

The paper feeding system is composed of three items: - two paper rolls supports with independent shafts- automatic roll replacement...

More details

ROBOTIC LOADING OF TPE INCAPSULATION PRESS

- Cleaner & Primer Preparation- IR Lamps Heating- Glass Squaring- Robotic handling- Spacers feedings and insertion- Press open for 10 sec- Glass positioning +/- 0,2 mm

More details

SEMI-AUTOMATIC SOLDERING ON HEATED BACKLIGHTS

It is a machine for lower production volume, the soldering heads are the same as those installed in automatic machines and their functioning is controlled likewise.Manual operations :- loading of a backlight into a pre-registered seat,- insertion of a terminal into each soldering head,- starting of...

More details

SIDELIGHTS DE-PALLETIZING

- One or two raws depalletizing- Interposed string aspiration- Cycle time: 5,5 sec- Automatic change over- Glass conveying

More details

EDGING OF MULTI-LAYER GLASS

- Edging according to the complex 3D design of the car frame- Hydraulic grinding wheel- Grinding wheel speed control- Contact pressure feed-back- Automatic wheel changing (rough, finishing, polishing)- Automatic periodical checks of the wheel wearing- Grinding wheel refrigeration

More details

PIN & SPACERS APPLICATION

Accurate, reliable and fast gluing of components by vision guide or with reference to glass edge. In line robotic or semiautomatic.

More details

The PUR Direct Glazing

Application of a polyurethane seal all along the glass windows edge with esthetical and protective purpose (patented technology).Flow rate changeable in two different zones of the profileJunction directly performed when the polyurethane is steel fluid with no need for intermediate storage and...

More detailsAreas of activity

Our mission is: to make your job easier and better through automation.

The daily confrontation with sectors constantly evolving in technological and highly specialized way is for us a constant incentive to grow and explore new horizons.

Our purpose is offering to our Customers modern and successful solutions, through automation, to solve production problems. In recent years we had great development and employ in areas such as farmaceutico, pharmaceuticals, food and in general in the manufacturing field with high production capacity, standard applications and tailor-made systems.

MoreWhere we are

ICAPlants s.r.l. - an ICAP Group Company

Direzione e Uffici: Via Coletta 10, 04100 (Latina) - Italy

Sede Legale: Via Coletta 10, 04100 (Latina) – Italy

C.C.I.A.A.: 133934

Partita IVA: 01944030590

+39 0773 26271

+39 0773 262746

Star s.r.l. - an ICAP Group Company

Direzione e Uffici: Via Coletta 10, 04100 (Latina) - Italy

Sede Legale: Via Coletta 10, 04100 (Latina) – Italy

C.C.I.A.A.: 160668

Partita IVA: 02298790599

+39 0773 26271

+39 0773 262746

ICAPtrading Shanghay Co. Ltd - an ICAP Group Company

XuHui Commercial Mansion, Room 719, No.168, YU DE Road, Shanghai 200030 (CHINA)

Marriott International B, Room 1501, Oriental Plaza, Erdao District, Changchun City

+86 21 34250259

+86 21 64397995

ICAP-NA, LLC (Oh) USA, founded on 26 September 2017!

Contact

Fill out the following form to receive information, we will reply within the next 24 hours !